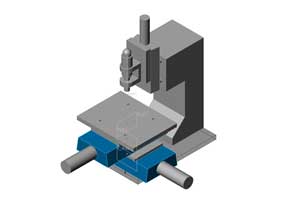

This is the Solidworks model of

the slides and frame.

|

I made a mock up out of MDF to see if the

envelope was going to be satisfactory. I ran the machine with a router

to make a couple parts.

|

This is the concrete column for

the Z axis slide. It took two 80Lb bags of concrete. The base is

engineered stone counter top material. This turned out a bit light, so

will be reinforced. I intended to use an 18x24x3 surface plate, but it

was just a little too small.

|

Here, the machine is building

itself. under the bag is the Zaxis slide and the router is facing and

drilling the mounting points for the Z axis.

|

The Z axis is mounted. The slides

are Aerotech units. 12"x12"x6" travels. The ballscrews are metric.

|

This is the power supply and

servo drive. There is 800W at 48V driving 3 and soon 4 Gecko 320

drives. One slot for the power supply was omitted so the drive could be

mounted.

|

The drive electronics are mounted

on an oversize heatsink The 3 prong socket plugs into the power rack

which was rewired to give the drive 48V instead of the 110VAC that

would normally be at that plug. In this picture it is not yet complete.

|

The machine as it stands on

10/4/06. The table is aluminum with t-slots. The spindle is a Precise

Super 45. I intend to make a mount for a Sherline or import minimill

spindle for heavier cutting. The power/drive rack and PC will be

mounted in the base of the machine. It needs a few more things. like Z

axis limit switches, way covers, reinforcement of the base plate, and

general tidying up of wiring.

|

|

|